Skip to: main navigation | main content | sitemap | accessibility page

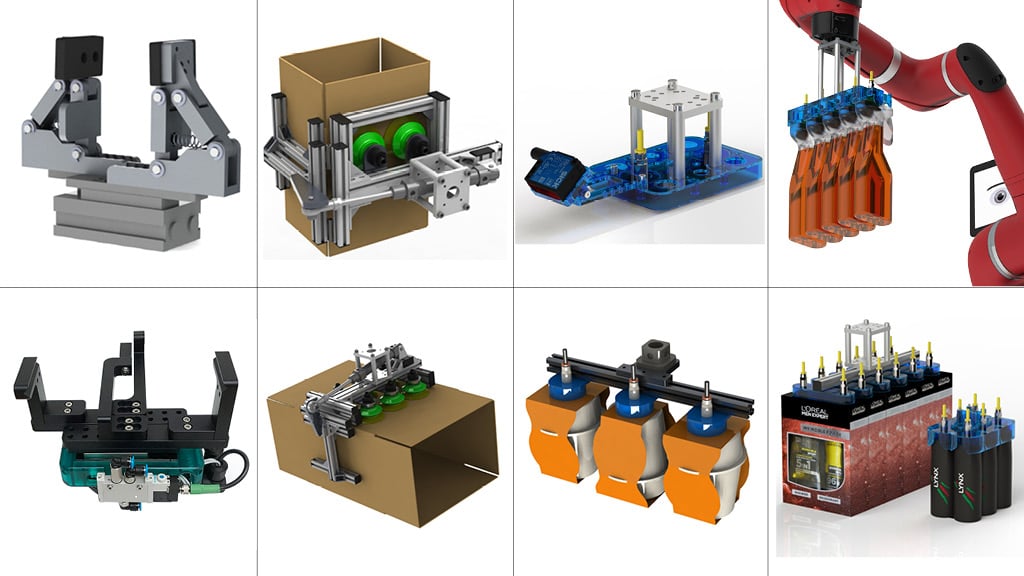

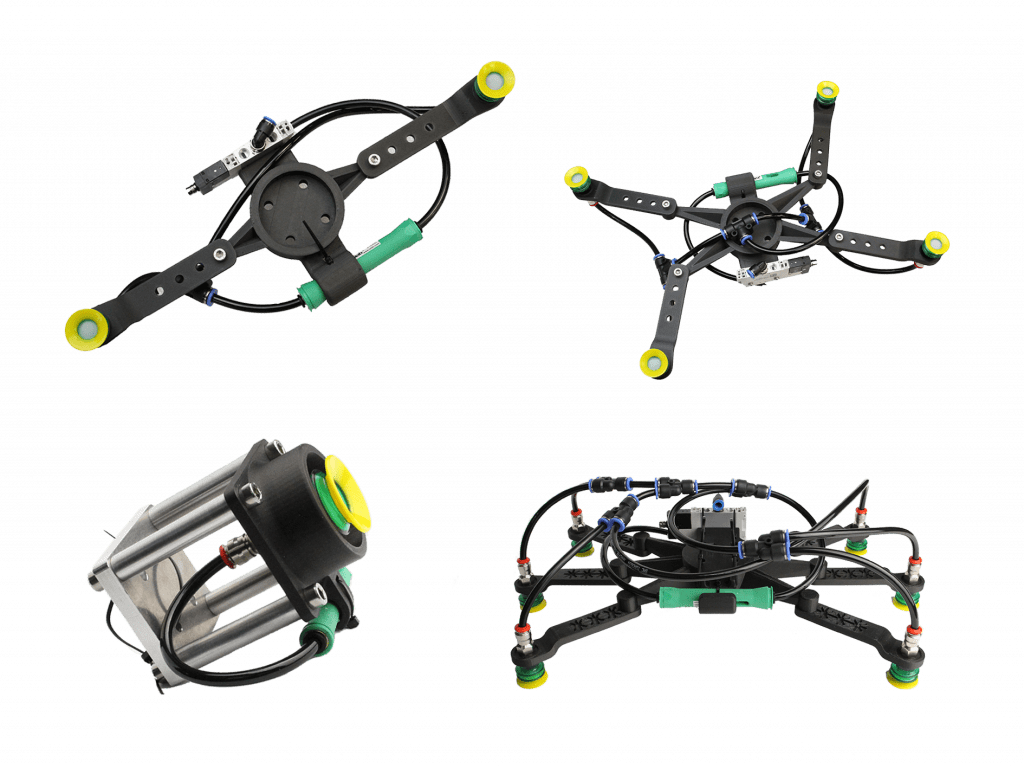

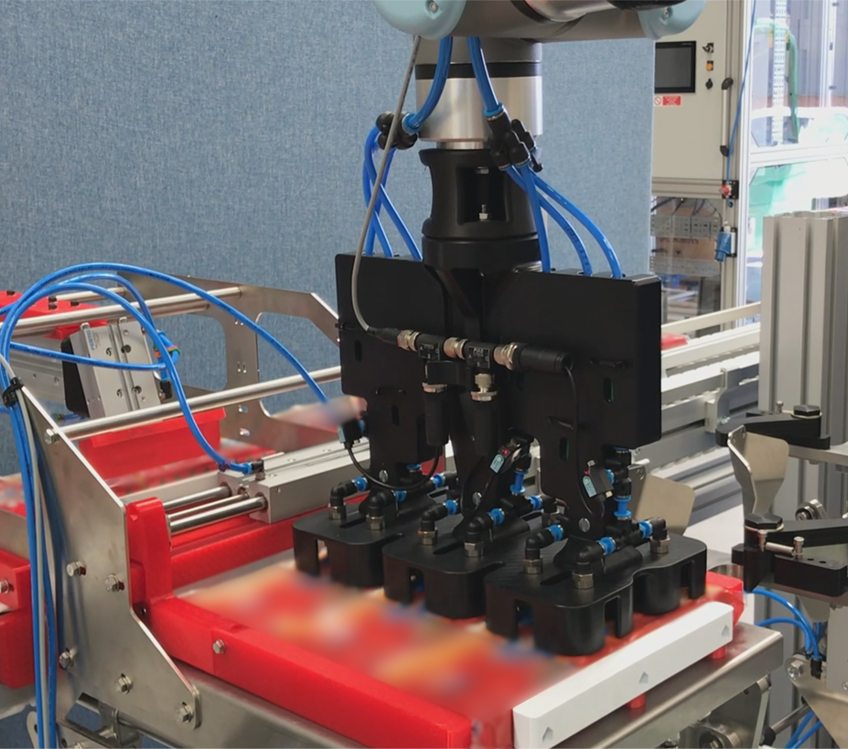

We understand that when it comes to robot end effectors, one size does not always fit all. The use of standard end-of-arm-tooling in specialist applications may compromise the performance of the entire automated process. To overcome such issues, a bespoke EOAT solution may be the only viable option that will allow you to get the most from your robot.

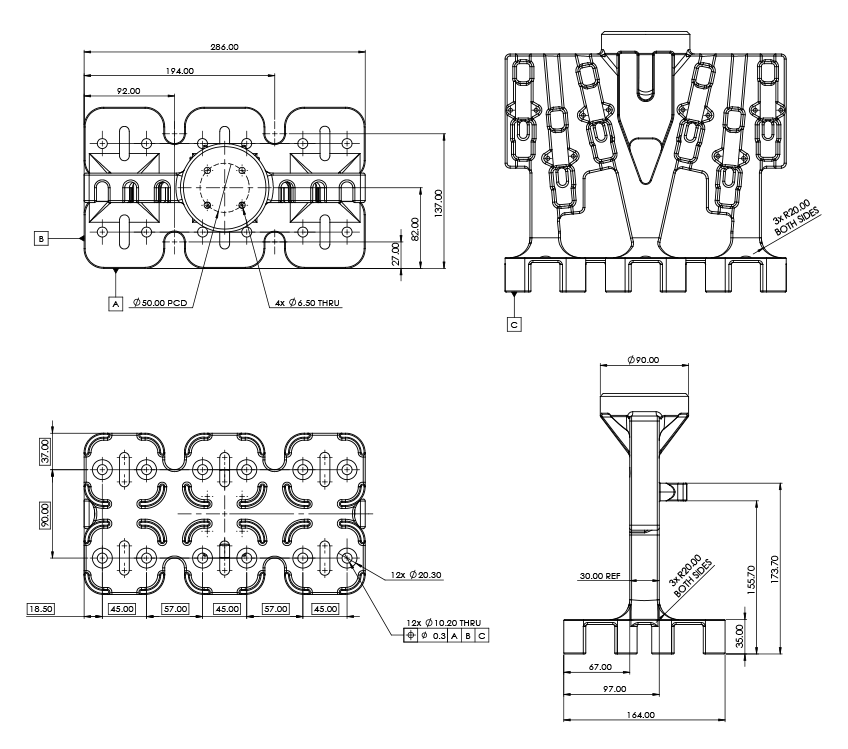

We are experts in developing extraordinary tools for extraordinary applications. Our in-house design proficiency combined with our rapid prototyping capability allows us to produce state-of-the-art end effectors for all types of robots with a super-fast turnaround.

We have a curated library of tried and tested custom tool designs that have the potential to be quickly and easily modified by our engineers to suit your needs. If a suitable design already exists for an industrial or a collaborative robot arm, this route is a highly cost-effective and time-saving means of finding a tool that will fulfil your required objectives.

Alternatively, we will design and develop a bespoke robot tool that meets your exacting requirements.

Why end-of-arm-tooling matters

The key to every successful robotic work cell implementation is EOAT functionality.

We place a strong focus on our designs and are proud to have developed some of the most innovative, robust and reliable tools. With robot users demanding more and more versatility in their work processes, the need for flexible and intelligent robot tools that add value to the overall system is paramount.

End-of-arm-tooling comes in all shapes, sizes and configurations. We have all the in-house capabilities to deliver all of your part handling requirements.

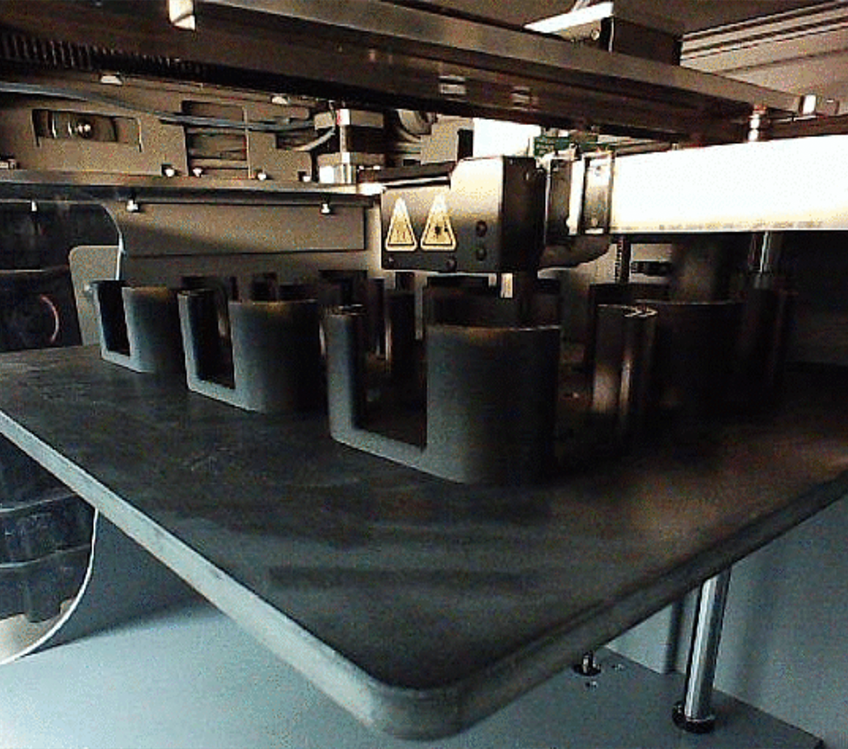

Our efficient design processes enable fast turnaround of tools for prototype purposes or short production runs.

Our efficient design processes enable fast turnaround of tools for prototype purposes or short production runs.

Our in-house project engineers have access to all the resources for the assembly and iteration of components.

Once built, a comprehensive testing programme is undertaken before our service team install and commission on-site.

![]()

© 2003 - 2024 Active8 Robots (Active Robots Ltd.) All rights reserved.